Ceramic Membranes For Wastewater Filtration An Overview

INTRODUCTION

Huge growth in population and economic development is constantly creating humongous pressure on existing water resources. Water in usable form is needed for drinking, industrial purposes and most human activities.

The water that we use does not exist in this pure and usable form. The water from a well or a river is turbid and contaminated with a vast variety of impurities like disease causing bacteria and protozoa (e.g., Cryptosporidium), plant nutrients and putrescible organic material, arsenic, iron, chemical compounds from industrial waste etc. Ceramic membrane systems are waste water purifying systems generating usable, hygienic and clean water by removing such impurities.

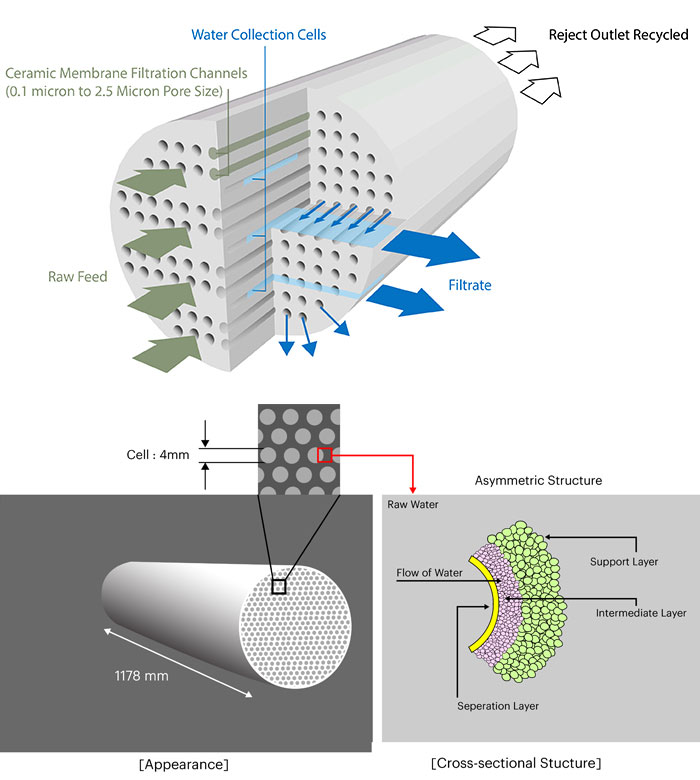

Endura, brand of Prism Johnson Ltd. is proud to introduce state of the art, in-house developed Ceramic Membranes for filtration of water, wastewater, process, non-water process and wide range of CIP applications. Made from Alumina (Al2O3), Titania (TiO2) or Zirconia (ZrO2), with various geometrics & pore size, ceramic membranes are alternative solution to conventional filtration & polymeric membranes having consistent performance.

ADVANTAGES OF CERAMIC MEMBRANES

1. High temperature & pressure resistance.

2. Excellent acid & solvent resistance.

3. Chemical stability, oxidation resistance.

4. High separation efficiency due to high porosity.

5. Can withstand entire pH range 0-14

6. Compact footprint area.

7. High mechanical strength that gives pressure, erosion, abrasion resistance.

8. Unlike other materials it is nontoxic and not known to be a carcinogen.

WASTEWATER TREATMENT CERAMIC FILTRATION

Oily waste water

Growing environmental concerns have fueled the need for efficient separation of oil-water mixtures. Oily wastewater causes extensive pollution to water and soil. It is produced from various sources, e.g. oil/gas recovery, oil refining, metal finishing, mining and transportation. Direct disposal of the oily wastewater is forbidden by the govt. regulations and oils in the oily wastewater should be removed to meet the discharge standards. Ceramic membrane filtration removes free and emulsified oily waste water.

Grey water treatment

Greywater, or Sullage, is commonly defined as wastewater generated from domestic activities such as laundry, dishwashing and bathing which can be recycled & reused on-site for low end applications. Ceramic membranes provide the most ecofriendly Grey Water Treatment.

Printing and Dyeing wastewater treatment

The textile & other printing industries are known to use huge quantities of water and release immense quantities of highly pollutingcoloured waste water containing difficult to remove components like dyes, pulp, bleaching agents, heavy metal residues, COD etc. Such water contains complex chemical pollutants that alter the acidity and basicity of water causing huge damage to water resources. Our ceramic membranes have been proven as a viable alternative to combat such toxic contamination and help in reuse of these effluents.

CONCLUSION

The super effectiveness of this technology over conventional filtration systems calls for

More research to design & discover cost effective, highly permeable, high quality material.

Reduction in cost of production, maintenance and high operational efficiency.

Ceramic membrane filtration is highly effective in certain complex wastewater effluent filtrations and research is needed to discover other forms of contaminations it can treat.

Thereby, providing for cost-effective water treatment to cater to extensive water requirements, replenishment and prevention of environmental damage.