Applications

CERAMIC MEMBRANES IN DAIRY INDUSTRY

The food and dairy industry has embraced ceramic membranes for their unique properties. There are a number of installations around the world using these products for their sanitization properties and durability.

The majority of ceramic membrane applications in the dairy industry are for Extended Shelf Life (ESL) milk where polymeric membranes simply will not work. In addition, there are systems operating that are used to defat whey, curd cheese and other dairy products. Another application that has been using ceramic membrane filtration is the fractionation of whey proteins in the cheese making process.

ENDURA, brand of Prism Johnson Ltd. has developed Microfiltration & Ultrafiltration Ceramic Membranes for dairy industry.

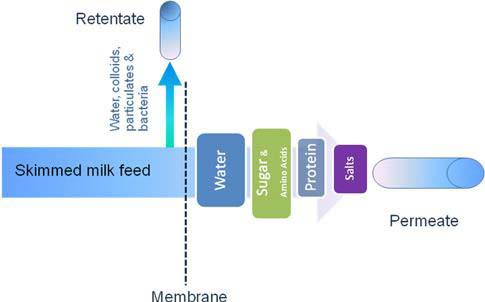

MICROFILTRATION (MF)

The microfiltration of milk concerns two main industrial applications

- Bacteria removal from skimmed milk.

- Selective concentration of casein micelles for cheese making.

| Pore Size | Molecular Weight Cut-Off | Pressure | Principle | Retentate Characteristics |

| 0.2 – 2.0 μm | > 200 kDa | Low, below 2.0 bar | Low pressure driven membrane process | Low retentate separation of protein, bacteria & other particulates |

MF APPLICATION & BENEFITS:

- Extended shelf life (ESL) cheese

- Consistent good microbial quality

- Extended shelf life (ESL) pasteurized milk

- Pre-treatment of UHT milk

- Spore removal for cheese milk

- Protein fractionation

- Whey protein recovery

- Brine purification

- Spore removal for whey

- Spore reduction for milk for powders (ESP Infant Formula products)

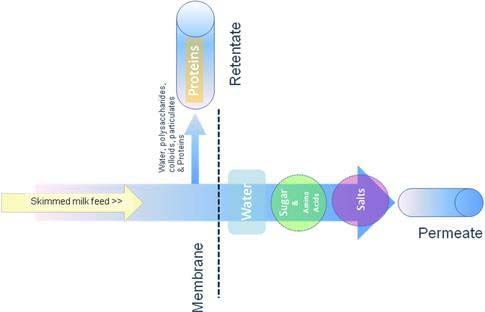

ULTRAFILTRATION (UF)

For more than 30 years UF has been used on milk processing plants.

- Standardization & Concentration of milk proteins.

- Concentration of whey proteins.

| Pore Size | Molecular Weight Cut-Off | Pressure | Principle | Retentate Characteristics |

| 1.0 – 500 μm | 1 - 200 kDa | Medium, 1.0 - 10 bar | Medium pressure driven membrane process to overcome the viscosity | Large retentate with casein micelles, fat globules, colloidal minerals, bacteria & somatic cells |

UF APPLICATIONS & BENEFITS:

- Ceramic and Spiral wound membranes for milk

- Liquid skimmed milk filtration for protein standardization

- UF Feta cheese filtration to preconcentrate the milk solids

- Cast Feta cheese

- Cheese milk protein standardization

- Quarg

- Cream cheese

- Milk protein standardization

- Whey protein recovery

- Lactose manufacturing

- Fractionation

- UF Processing, Filters, Technology

- Ultra filtered milk

- Extended shelf life, long life

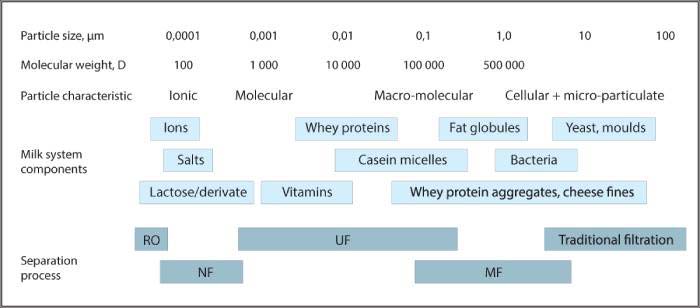

Introduction of membrane technology into dairy science witnesses phenomena of mutual benefit for membranes as well as for dairy industry. Below is the summary table of various size & types of membrane applications.

The marked improvement in the nutritive quality and sensory attributes of the existing dairy products with higher yields in addition to development of several innovative dairy products became possible by the application of membrane technology. Continuing the efforts for the development of superior membranes will further expand the role of membranes in dairy processing.