Applications

CERAMIC MEMBRANES FOR PROCESS & NON-WATER PROCESS APPLICATIONS

“Let us recover & convert wastes to valuable resource and save energy with latest sustainable technologies”

Endura, brand of Prism Johnson Ltd. is proud to introduce Lab Scale, Pilot, Packaged, Mobile, Tailor-Made Process & Non-Water Process units with state of the art, in-house developed Ceramic Membranes with complete design & engineering, system integration in collaboration with other world class technology providers for multiple applications & multiple industries.

PROCESS WATER APPLICATIONS:

- Drinking Water

- RO Pretreatment for Brackish Water & Desalination

- Pretreatment to Demineralization

- Side Stream Filtration

- Process Water for Food Contact

- Ingredient Water for Beverages

- Evaporator Condensate Polishing

- Tire Condensate Polishing

- Fruits & Vegetable Fume Water

- Process Water Cleanup & Recycle

- Boiler Condensate Polishing

- Process Condensate Polishing & Treatment

- Removal of Oil

- Oil Filtration

- Removal of Iron

- Removal of Heavy Metals

- Swimming Pool Side Stream Filtration

- Mining Industry Wastewater

- Car Wash Stations

- Grey Water Treatment

NON-WATER PROCESS APPLICATIONS:

Fine Chemistry/Pharmaceutical Industry:

- Gentle API concentration & purification

- Non-Thermal solvent recovery & management

- Room temperature solvent exchange

- Broths for antibiotics production

- Amino acids production

- Enzyme solutions

- Purification of organics

Oil & Petro Chemistry:

- Removal of tar components in FCC feed

- Purification of gas condensates

- Purification & desalination for nanometer particles slurry

- Dewaxing

- Used oil recovery

Bulk Chemistry:

- Continuous recovery of homogeneous catalysts

- Decolorization of products

- Product polishing

Natural Oils & Products:

- Fractionation of crude extracts

- Enrichment of natural compounds

- Natural oil processing

- Gentle separations

Food & Beverage Applications:

- Lactose & cheese whey concentration

- Milk concentration

- Cheese whey desalting

- Brine clarification

- Pharma grade lactose

- Demineralization of milk product

- Protein retention

- Yogurt concentration & fat removal

- Fruit & vegetable juice

- Clarification of Vinegar, Soy

Sugar & Alcohol Applications:

- Concentration of diluted sugar streams

- Sugarcane Juice Clarification

- Agribusiness

- Sugar concentration

- Wine adjustment

- Wine de-acidification

- Wine clarification

- Whisky distillation recovery

- Corn wet milling

Biofuels:

- Acetic acid purification & concentration

- Concentration of aqueous sugar streams

- Separation of dissolved chemicals from an aqueous sugar stream

- Separation of hemicelluloses sugars from dilute acetic acid solutions

- Purification of organic acids from fermentation processes

- Ethanol purification

Dextrose Purification:

- Sugar fractionation

- Sugar demineralization

Metal Industry:

- Chromic Acid removal & recovery

- Recovery of Nickel & Copper

- Recovery of Precious Metals

- Recovery of Copper

- Recovery of Tungsten

- Purification of Phosphoric Acid

- Purification of Nickel Sulfate

Sludge Treatment:

- Faecal Sludge Treatment

- Leachate Treatment

- Sewage Treatment

- Oil & Grease Removal from CNC Machines

Features:

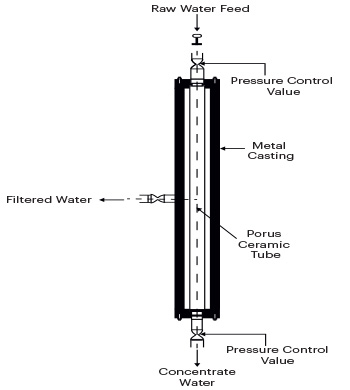

- In-house Ceramic Membranes

- Conventional & Specialty Resins

- Tubular Membranes

- Integrated Membranes with MF/UF/NF/RO

- Pervaporation/Vapor Permeation Membranes

- Main components on the skids consists of membrane modules, feed tank, centrifugal/dosing pump, instruments, back flush tank, CIP unit, control panel, valves, piping.

- Material of construction like SS304, SS316/316L, Titanium, FRP, UPVC, CPVC

- Material of seals like EPDM, Fluoro Rubber, Silicon

FAQ

Unlike polymers, ceramic membranes don’t degrade under harsh conditions, last longer, and offer superior filtration in diverse chemical processes.

Yes, ceramic membranes are ideal for recovering solvents in chemical and pharmaceutical industries due to their chemical and thermal stability.

Absolutely. Ceramic membranes are used for protein concentration, wine clarification, juice purification, and dairy filtration with high purity standards.

Ceramic membranes resist aggressive acids, alkalis, and solvents, making them reliable in non-aqueous and high-pH industrial processes.

Yes. Ceramic membranes offer sterile filtration for APIs, catalysts, and intermediates, ensuring consistency and safety.