Applications

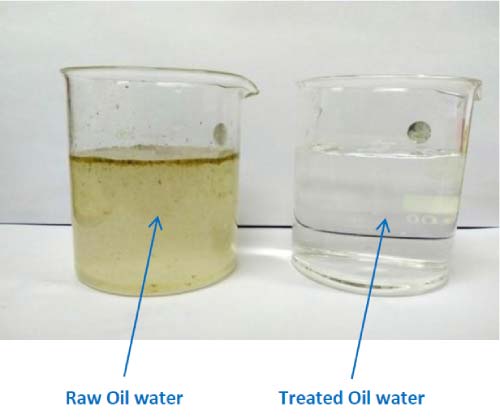

OIL WATER SEPARATION WITH CERAMIC MEMBRANES

Growing environmental concerns have fueled the need for efficient separation of oil-water mixtures. Oily wastewater causes extensive pollution to water and soil. It is produced from various sources, e.g. oil/gas recovery, oil refining, metal finishing, mining and transportation.

Direct disposal of the oily wastewater is forbidden by the govt. regulations and oils in the oily wastewater should be removed to meet the discharge standards

ENDURA, brand of Prism Johnson Ltd. is pleased to introduce Oil water Separation Plants with Ceramic Membranes. The membranes effectively & efficiently remove the oils from oily wastewater.

Ceramic Membrane Water Filtration provides a highly desirable method for treating oil wastewater containing emulsified oils due to its energy efficiency, ease of processing and low maintenance cost.

Ceramic Membranes have revolutionized the filtration methods & technologies due to following advantages;

- Longer service life than polymeric membranes

- High temperature & pressure resistant

- Higher stability against both polar and chlorinated solvents

- Superior chemical & abrasion resistance

- Can withstand pH from 0 – 14

- Stability against high oil fractions present in industrial wastewater

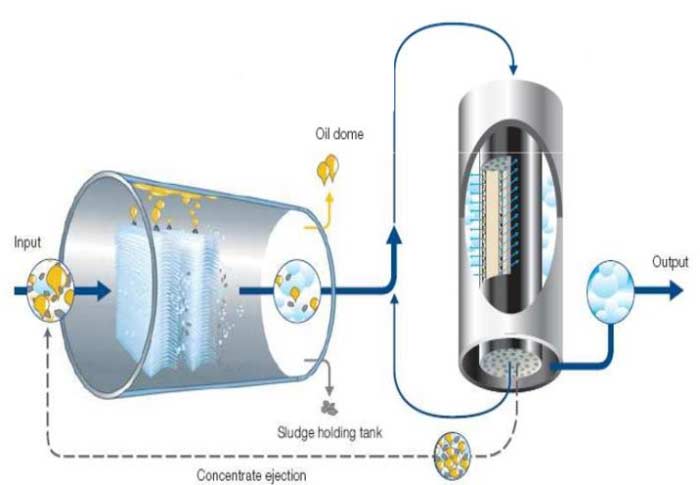

Oil-Water Separation Process:

Stage 1 of Oil Water Separation Process

Multiphase Separation Profiles;

- Oil, Water & Solids are separated.

- Use of coalescence + adhesion to form larger oil droplets flowing upwards.

- Solids slide down the profiles into the sludge holding tank.

Stage 2 of Oil Water Separation Process

Membrane Filtration;

- Residual oil is pressure separated in the membrane by cross flow principle.

- Periodically backflushing.

- Automatic oil discharge.